-

-

QC Economical

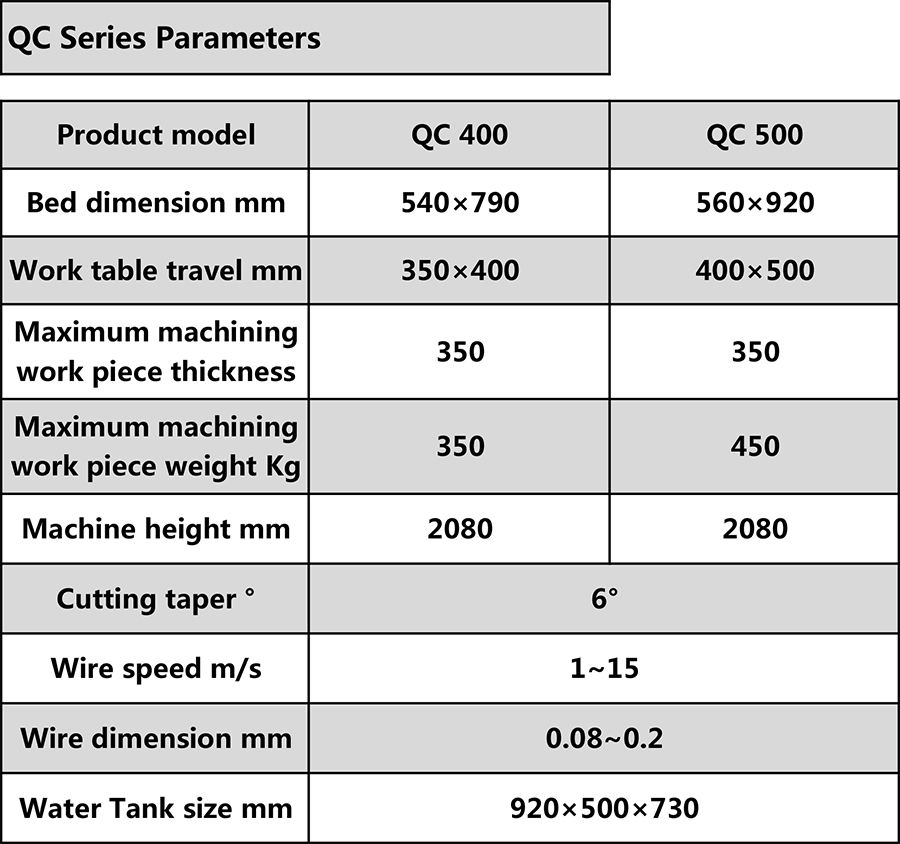

QC series is the latest generation of full intelligent wire cutting machine equipped with the core technology of WIDCS. ...

Support hotline:+86 18980636354

E-mall:litina-cc@hotmail.com

- Details -

▶ QC series is the latest generation of full intelligent wire cutting machine equipped with the core technology of WIDCS. It is the step drive version of TC series. This series are widely used in precision mold processing and precision parts bulk processing in small and medium-sized enterprises.

▶ X/Y axis is driven by Japanese Panasonic servo motor,X/Y/U/V/Z adopts linear guideway ball screw structure,Z axis can be automatically controlled to rise and fall. Adopt the structure of slow-feeding wire cut machine bed and slow-feeding wire cut control mode,it has high reliability and high stability of processing.It has realized the function of automatic wire feeding and intelligent wire tightening.

- Series features -

▶ Series Features:

1.The machine body and worktable are fully supported by machine center,which greatly improve the movement of the machine rigidity and reliability of the long-term use of the machine.

2.X, Y axis are Taiwan high precision linear guide rail and double nut pre-tightening ball screw, adopts synchronous belt preload transmission structure. It ensure the high precision of the machine for a long time, avoid the transmission error when moving.

3.Tightening system adopts original core technology. Dual sensor bidirectional adaptive AC servo full closed loop dynamic tension control system, which can control molybdenum wire rough cutting, trimming wire, change tension, tightening wire and large area dressing (obtained invention patent and software copyright certificate). It is the key technical guarantee of stability and consistency.

4.The wire guide adopts the design of slow-feeding wire-cut machine. UV axis use a unique built-in vertical structure design (obtained a national patent).

5.Z axis adopts precision linear guide ball screw, wire guide lifting repeated position accuracy 0.001, maximum proximity to the work-piece surface, prevents the wire shaking again, avoids the line mark on the cutting surface, and greatly improves the precision and roughness of the machining surface.

6.Over-length drum, the guide rail adopts imported linear guide rail and inductive reversing switch to ensure the smoothness, high precision and long-term reliability when operating the drum with high and low speed.

7.The machine castings adopt resin sand molding technology and vibration aging treatment to eliminate internal stress and keep the machine accuracy unchanged for a long time.

8.Drum bearing and all machine bearings are Japanese NSK bearing. It makes the machine finish more reliability and durability, so that ensure the long-term benefits of customers.

9.The filter system use the slow-feeding wire-cut machine filter system, which has the characteristics of high filtration precision and long service life of working fluid.

- Accessories display -

- 360°Panoramic display -

-

Sales Centre: Sichuan Shenyang CNC Machinery Co., Ltd

-

Support hotline:+86 028-84323532Support hotline:+86 13508323732

-

Fax:+86 028-84368573P.C.:610061

-

Sales Centre Address:No.2302, Fulin Building, #388 Shuanglin Road, Chengdu of Sichuan, China

-

Addrres:No.106 Liangshuijing Road, Daan District, Zigong of Sichuan, China

-

Chongqing Office Address:Keyuan 2nd Road, Jiulongpo District, Chongqing

-

Address of Beijing Office:taihualongqi square, huangtudian, Huilongguan town, Changping District, Beijing

-

Fujian Office Address:banxiali, xihongtang community, Tong'an District, Xiamen City, Fujian Province

Wechat

Wechat